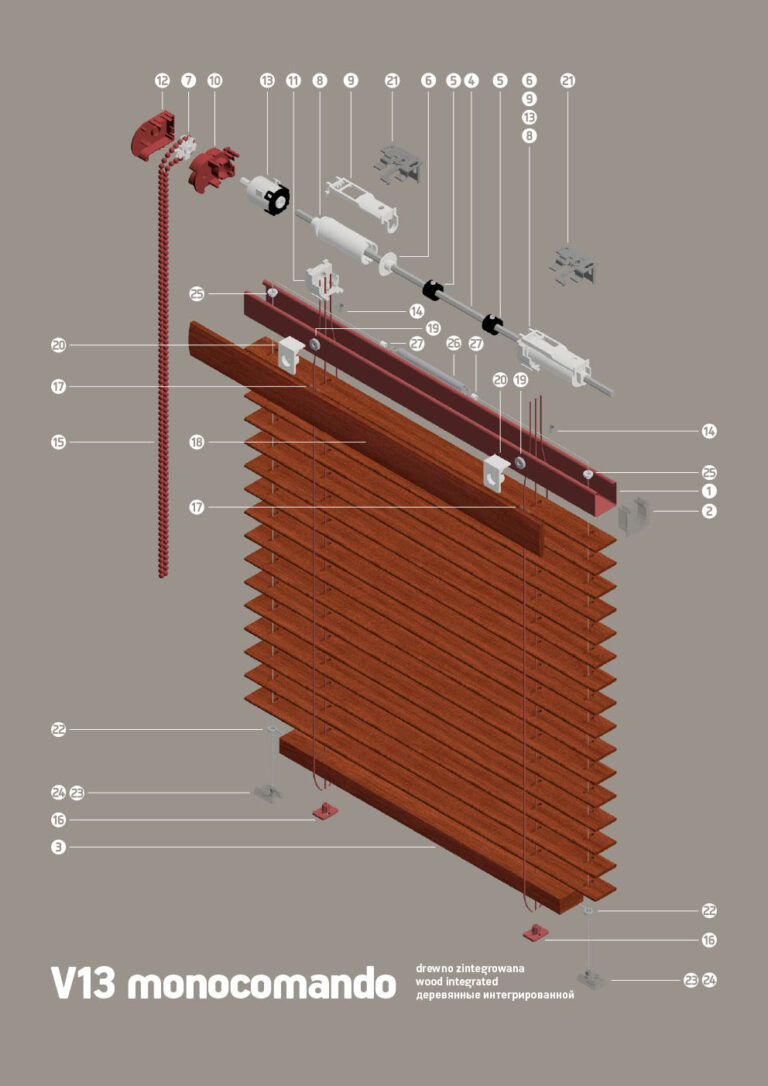

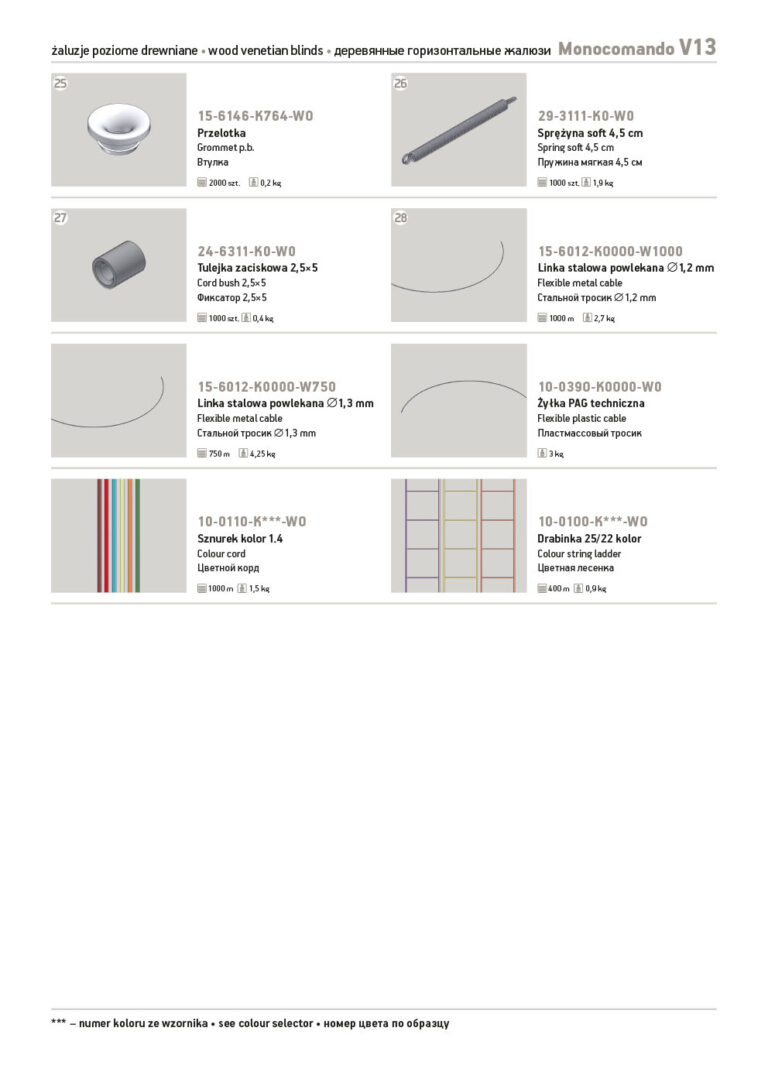

V13 Wood Monocomando

Product description

V17 Monocomando wood system is a wooden blind based on 25 mm wide wooden slats.. It is designed for internal use in a free-hanging system. The blind is operated only by chain “lifting / lowering / adjusting the inclination” of slats, which works with a self-braking mechanism that prevents the blind from falling automatically.

Available types of V13 Monocomando wood system:

- Standard – basic version

- Side guiding – the venetian blind has additionally stabilizing cables for lowering and lifting and keeping the slats close to the window pane.

Production technology

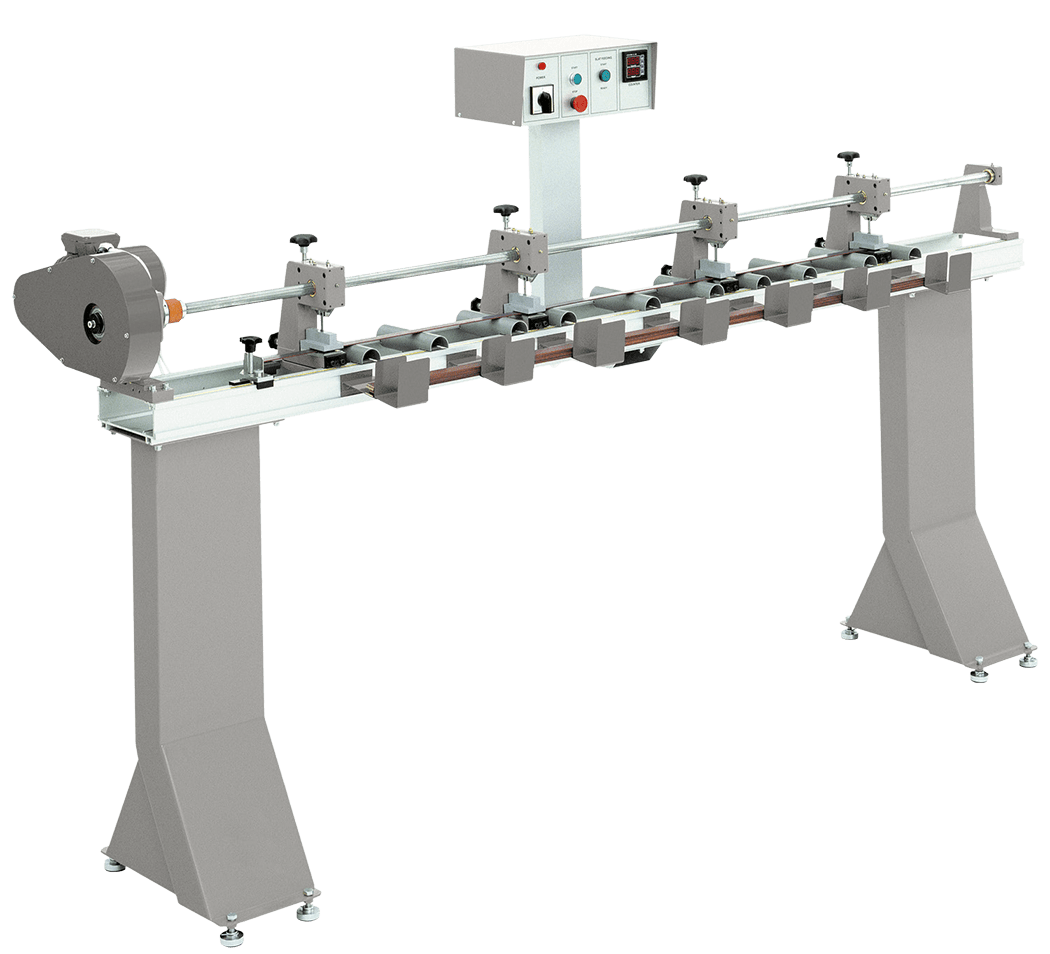

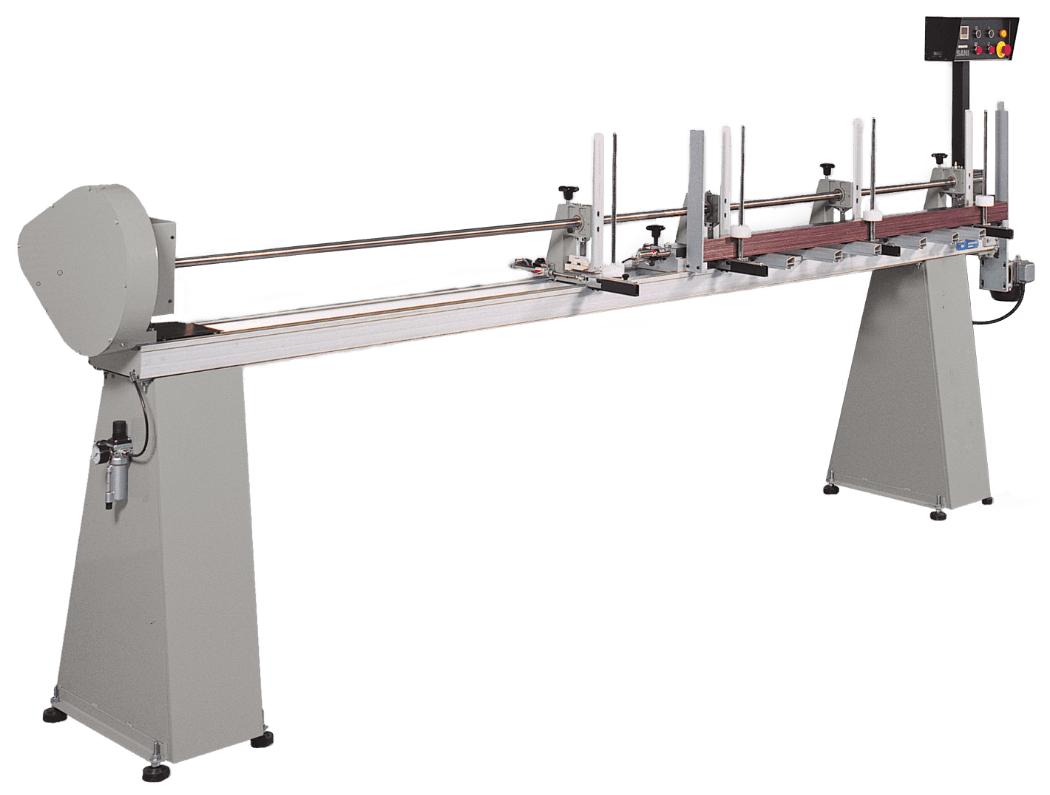

M400RD is a semi-automatic machine for wooden blinds production.

Machine features

- All holes punched simultaneously

- Slat width range 24-52 mm

- Manual feeding and removing of slats

Additional equipment

- Punching stations for side guiding holes

| Wood slats width | 25 mm, 35 mm, 50 mm |

|---|---|

| Max. length of wood slat | 2500 mm |

| Number of punching stations | 4 |

| Min. distance from slat edge to first hole | 70 mm |

| Power supply | 3x400V / 50-60 Hz |

| Installed power | 0,75 kW |

| Net weight | 160 kg |

| Gross weight | 310 kg |

| Packing – 1 wood box (H x L x W) | 2750mm x 670mm x 1670mm |

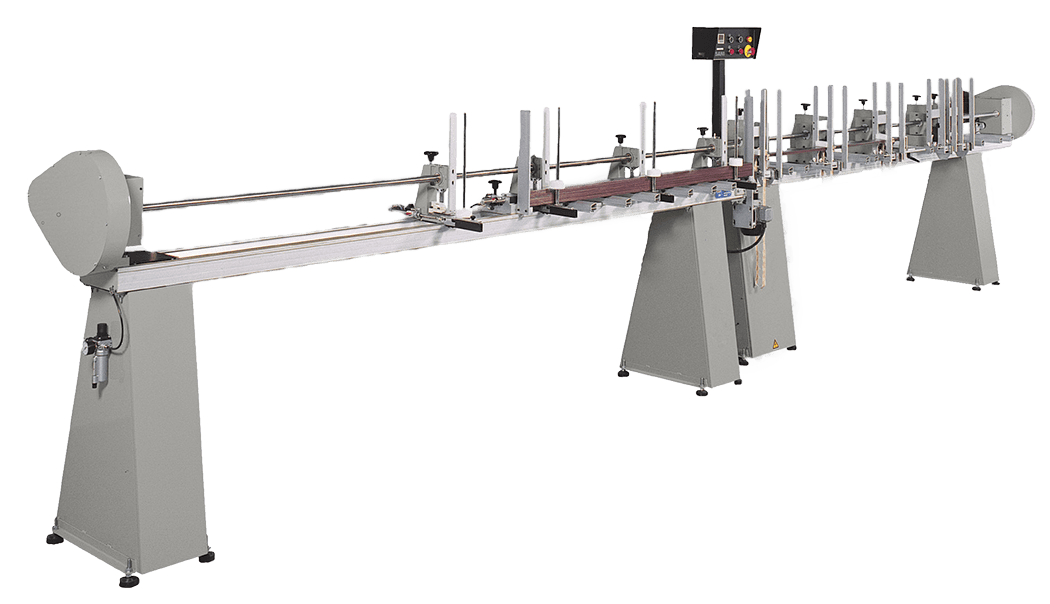

216WAF is a fully automatic machine for production of wooden blinds.

Machine features

- All holes punched simultaneously

- Adaptable for most wooden or composite slats 24-52 mm wide

- Precise setting of slat length and punching stations position

- Easy to operate and maintain

- Spare punches available

- 216WAF can be upgraded to 216W-219W at later occasion

Additional equipment

- Speed control

- Spare parts kit

- Service agreement

| Power supply | 3 x 220/240V (50/60 Hz)nlub 3 x 380/415V (50/60 Hz) |

|---|---|

| Pneumatic equipment requirements | approx. 6 bar at 30 L/min. |

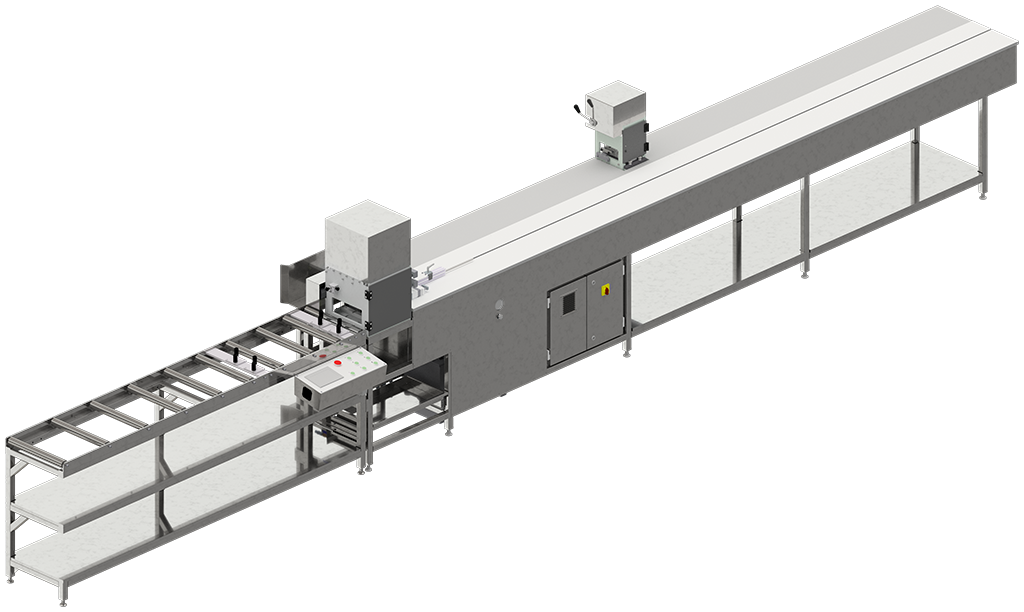

216W-219W is a fully automatic machine for wooden blinds production.

Machine features

- All holes punched simultaneously

- Adaptable for most wooden or composite slats 24-52 mm wide

- Adaptable for various slat widths and ladder types

- Precise setting of slat length and punching station positions

- Easy to operate and maintain

- Spare punches available

Additional equipment

- Magazines for woven laddertapes

- Speed control

- Spare parts kit

- Service agreement

| Power supply | 3 x 220/240V (50/60 Hz)nlub 3 x 380/415V (50/60 Hz) |

|---|---|

| Pneumatic equipment requirements | approx. 6 bar at 30 L/min. |

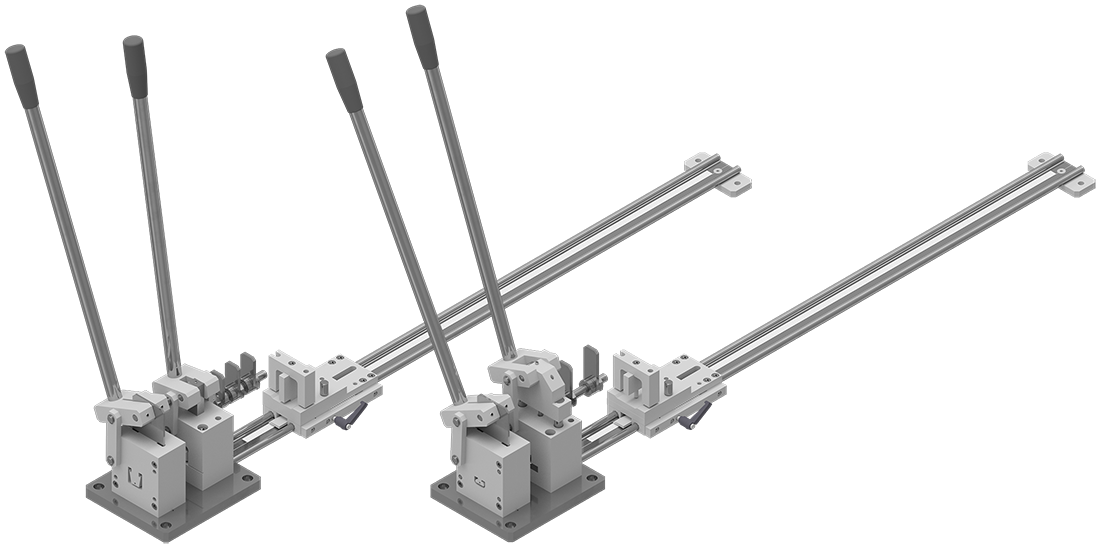

PR-5 hydraulically powered rail-cutting and punching machinery computerized with manual feeding with interchangeable dies.

Machine features

- Computerized automatic rail cutting and punching machine

- Interchangeable dies make it compatible with most rail systems

- Automatic calculation, only rail width must be entered

- Head and bottom rails punched at the same time

- Equipped with to tools for punching cord lock and tilter holes

- Easy to operate and maintain

- Service and after sale support

Additional equipment

- Software for barcode reader

- Side guide hole dies with on/off function

- Slopped blinds application

- Label printer connection

| Cut length | 3000, 4000, 5000 mm |

|---|---|

| Power supply | 3 x 380/415V 50/60 Hz |

| Weight | 780 kg |