V11 STANDARD

Product description

V11 system is a venetian blind based on head rails 27 mm x 19 mm with the possibility of using either aluminum slats 25 mm or 16 mm. Intended for internal use in a free-hanging or doube-glazing system.

Available types of V11 system:

- Standard – basic version, slat tilting is adjusted with a wand assembled with a tilter, lifting / lowering with cords.

- Double-glazing – is used in old-style windows, with a usage of a cable running through a window frame; slat tilting is adjusted with a wand connected with a cable running through a window frame.

Production technology

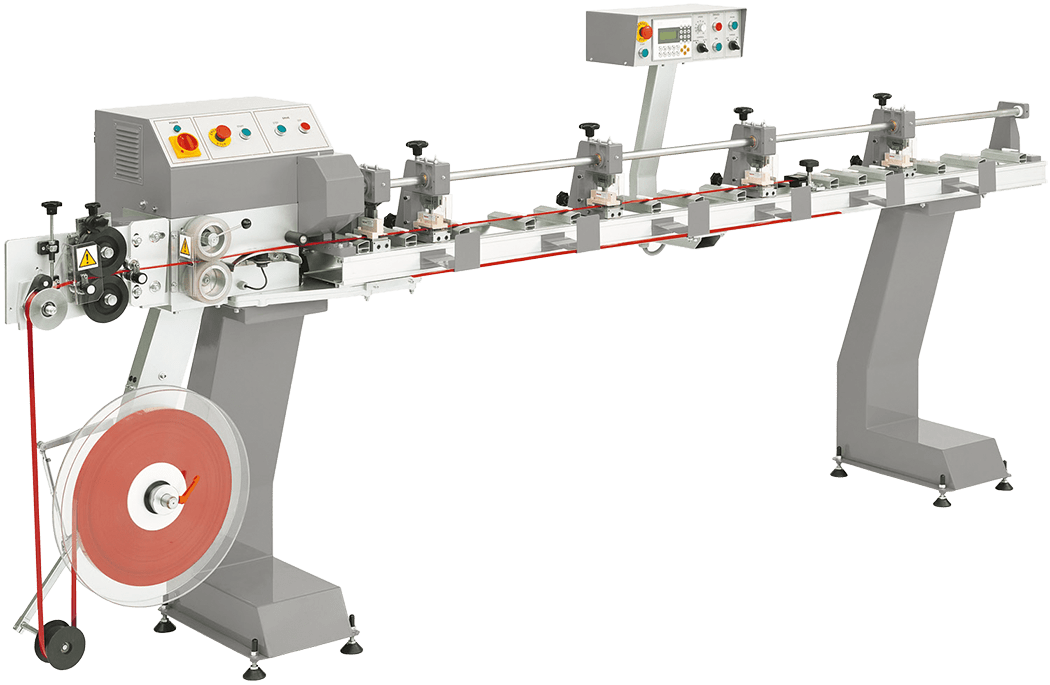

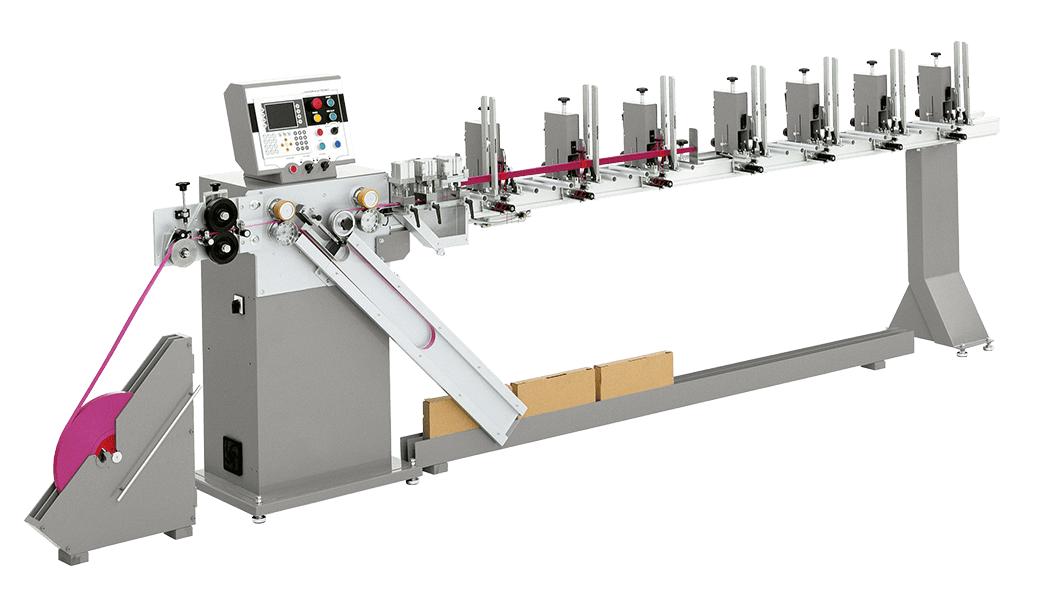

M600 manual slat forming, punching and cutting machine. Modular construction allows to upgrade this machine to fully automatic if needed.

- Forming, cutting and hole punching in aluminium slats

- Precise setting of slats length and punching stations

- Standard slat width range: 16, 25, 35 i 50 mm

- Quick and easy change between aluminium slats widths without using additional tools

| Slat width | 16, 25, 35, 50 mm |

|---|---|

| Min. length of cut slats | 240 mm |

| Qty of punching stations | 4 |

| Qty of cut off stations | 1 |

| Min. distance from slat edge to first hole | 70 mm |

| Net weight | 140 kg |

| Packing – wood crate (L x W x H) | 3900 x 500 x 730 mm |

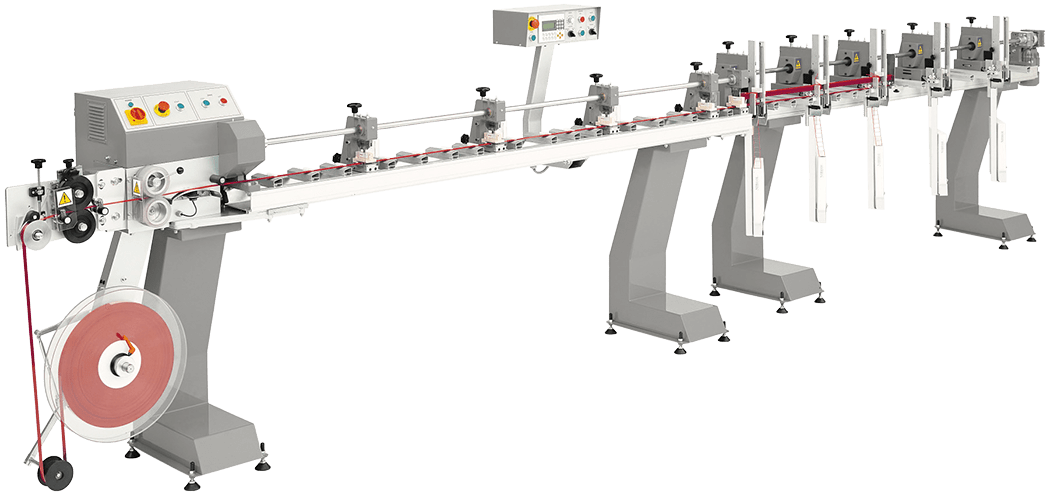

M420 is fully automatic slat cutting and punching machine.

- Cutting and punching in one cycle

- Precise setting of slat length and punching stations

- Variable speed: 0 – 100 %

- Standard slat width range : 16, 25, 35, 50 mm, on client’s wish

- Quick and easy change between aluminium slats widths without using additional tools

- Automatic qty of slats and hole division calculation

- Possibility to install threading section

- Easy to operate and maintain

- Side guide hole equipment

- Barcode reader

- Spare parts kit

- Service agreement

| Slats width (on client’s order) | 16, 25, 35, 50 mm |

|---|---|

| Slat length | 210 mm – 3000 mm |

| Qty of punching stations | 4 |

| Qty of cutting stations | 1 |

| Min. distance from slat edge to first hole | 70 mm |

| Max. slat feeding speed | 3 m/sec. |

| Power supply | 230V / 50-60 Hz |

| Installed power | 1,4 kW |

| Net weight | 230 kg |

| Gross weight | 480 kg |

| Packing – wood crate (L x W x H) | 4320 x 700 x 1650 mm |

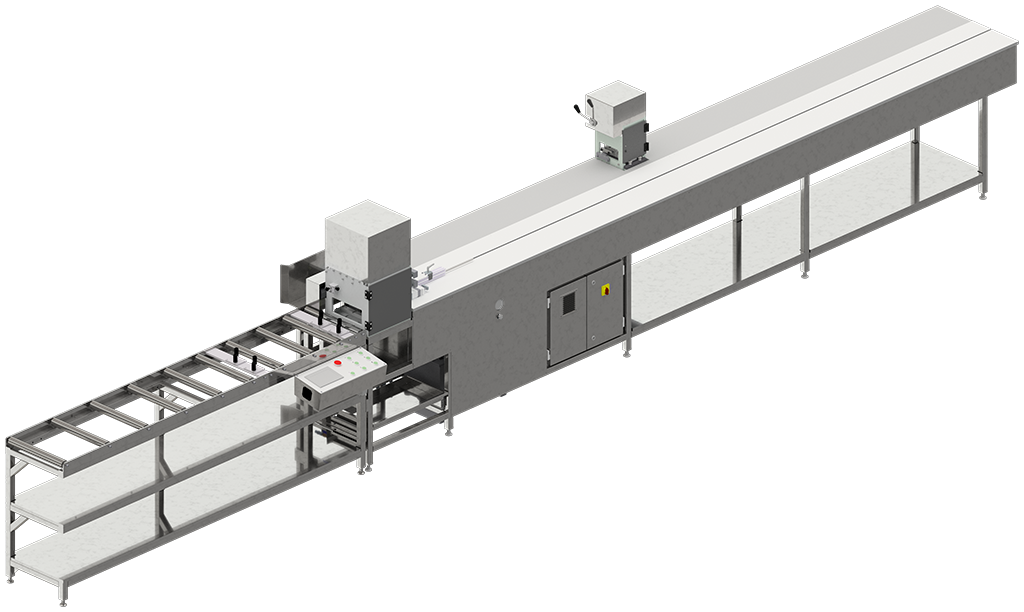

M420T is fully automatic slats cutting, punching and threading machine.

- Cutting, punching and threading in one cycle

- Precise setting of slat length and punching stations

- Single or double stacking magazines

- Mechanically disengageable punching dies

- Variable speed: 0 – 100 %

- Standard slat width 16, 25, 35, 50 mm

- Quick and easy change between aluminium slats widths without using additional tools

- Automatic qty of slats and hole division calculation

- Easy to operate and maintain

- Side guide hole equipment

- Multi blind cutting station (200 MC – compressed air required (0.6 MPa))

- Barcode leader

- Spare parts kit

- Magazines for woven laddertapes

- Short blinds kit (200 SB – compressed air required (0.6 MPa))

- Service agreement

| Cutting length | 290 mm - 3000 mm (longer optional) |

|---|---|

| Qty of punching stations | 4 |

| Qty of cut off stations | 1 |

| Qty of threading stations | 5 – 8 |

| Min. distance from slat edge to first hole | 75 mm |

| Max. slat feeding speed | 3 m/sec. |

| Power supply | 230V / 50-60 Hz |

| Installed Power | 1,9 kW |

| Net weight | 360 kg |

| Gross weight | 720kg |

| Packing – wood crate (L x W x H) | 4700 x 1120 x 1650 mm |

M4000 is fully automatic slats cutting, punching and threading compact machine of 3rd generation.

- Forming, punching, cutting and threading

- Production with high accuracy

- Compact machine – less space required

- All systems of venetian blinds production

- Numerically controlled length of slats

- Quick and easy change between aluminium slats widths without using additional tools

- Quick setup of blinds dimensions

- Slat coil holder with a constant slat tension

- Automatic slats number calculation

- Possibility to set another blind during machine work

- Diagnostic through service window or Internet modem

- Continuous readout:

- Productivity

- Qty of produced blinds

- Number of cycles per each die

| Machine type | M4000 NCS | M4000 MS |

|---|---|---|

| Number of punching stations | 3 | 3 |

| Number of cutting stations | 1 | 1 |

| Number of threading stations | 5-7 | 5-7 |

| Slat width range | 16, 25, 35, 50 mm | 16, 25, 35, 50 mm |

| Min. slat length | 300 mm – less without threading | 300 mm – less without threading |

| Max. slat length | 3000 mm, 3500 mm, 4000 mm | 3000 mm, 3500 mm, 4000 mm |

| Min. distance from slat edge | 80 mm – less without threading | 80 mm – less without threading |

| Production speedy (slat package 1 m x 1 m) | 31 sec. | 34 sec. |

| Control panel | 10,4inch colour touch screen | 10,4inch colour touch screen |

| Punching dies setup | automatic | automatic |

| Threading stations setup | automatic | manual |

| Package lifting to higher level | standard | standard |

| Short blinds kit | optional | optional |

| Barcode reader | optional | optional |

| Power supply | 3x400V / 50-60 Hz | 3x400V / 50-60 Hz |

| Installed power | 2,8 kW | 2,2 kW |

| Compressed air | 0,7 MPa | 0,7 MPa |

| Air consumption | 150 L/min. | 150 L/min. |

| Net weight | 440 kg | 395 kg |

| Gross weight | 655 kg | 610 kg |

| Packing – 2 wood boxes (L x W x H) | 1600 mm x 750 mm x 1800 mm | 3650 mm x 800 mm x 1645 mm |

PR-5 hydraulically powered rail-cutting and punching machinery computerized with manual feeding with interchangeable dies.

- Computerized automatic rail cutting and punching machine

- Interchangeable dies make it compatible with most rail systems

- Automatic calculation, only rail width must be entered

- Head and bottom rails punched at the same time

- Equipped with to tools for punching cord lock and tilter holes

- Easy to operate and maintain

- Service and after sale support

- Software for barcode reader

- Side guide hole dies with on/off function

- Slopped blinds application

- Label printer connection

| Cut length | 3000, 4000, 5000 mm |

|---|---|

| Power supply | 3 x 380/415V 50/60 Hz |

| Weight | 780 kg |

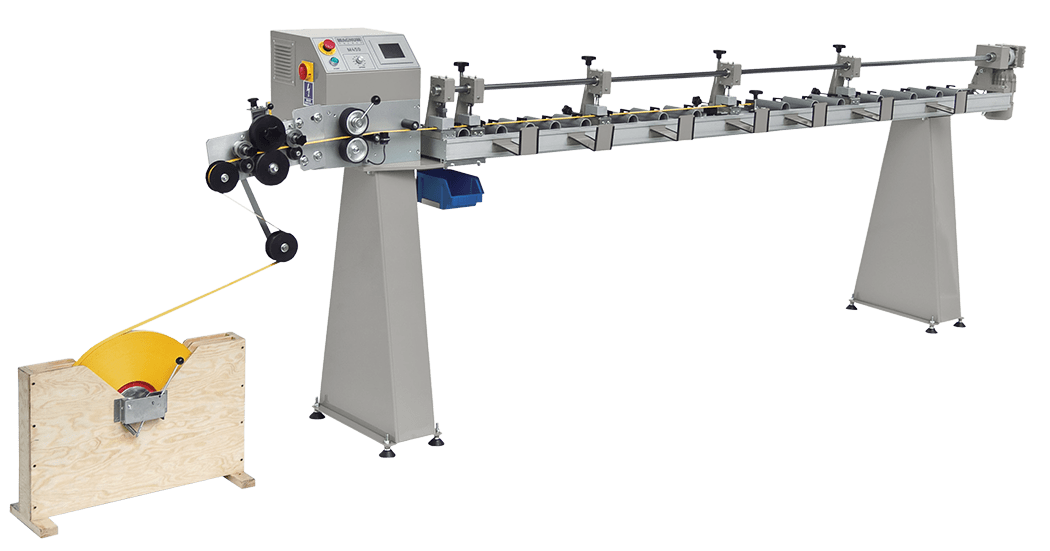

M450 is an automatic slat cutting and punching machine designed especially for small and medium blinds manufacturers.

- Forming, cutting and hole punching in aluminium slat

- Precise setting of slat length and punching station positions

- Variable speed 0-100%

- Standard slat widths 16, 25 mm

- Quick and easy change between slats widths without using additional tools

- Automatic slat counting during production process

- Modern „touch screen” control panel

- Side guide cut off die

- 25 mm or 16 mmm slat width equipment

- Warranty and non-warranty service

| Slats width | 16 mm or 25 mm |

|---|---|

| Slat length | 210 mm – 3000 mm |

| Number of punching stations | 4 |

| Number of cutting stations | 1 |

| Min. Distance from slat edge to first hole | 70 mm |

| Max. slat feeding speed | 1,7 m/sec. |

| Power Supply | 230 V / 50-60 Hz |

| Installed Power | 0,95 kW |

| Net weight | 190 kg |

| Gross weight | 490 kg |

| Packing – wood crate (L x W x H) | 4140 x 730 x 1630 mm |

M3000 is a fully automatic slat cutting, punching and threading machine.

- Forming, cutting and punching holes in aluminium slats 15, 16 or 25 mm wide and threading of venetian

blinds - All systems of venetian blinds production

- 2 punching stations allowing simultaneous punching of 2 holes

- Possibility of changing distance for side guiding holes

- Threading stations – manual setup

- High precision of blind length and setting of hole distance

- Automatic lift of produced blinds to a higher level – option

- Control panel – functions:

- Quick setup of blinds dimensions, automatic slat number calculation

- Possibility to set 6 types of blinds, also during machine work

- Possibility to choose qty and arrangement of holes and ladderstrings

- Readout of machine performance in m2/h, alu slats usage, qty of produced blinds and qty of cycles per each die

- Diagnostic through service window or Internet modem

| Number of punching stations | 2 |

|---|---|

| Number of cutting stations | 1 |

| Number of threading stations | 4-7 |

| Slat width | 15 mm, 16 mm, 25 mm |

| Min. slat length | 300 mm less without threading |

| Max. slat length | 3000 mm |

| Min. distance from the slat edge to the first hole | 90 mm |

| Machine productivity | 65 m2/h |

| Control panel | 5,7inch Monochromatic |

| Punching stations setup | automatic |

| Threading stations setup | manual |

| Package lifting | option |

| Barcode reader | option |

| Power supply | 3x400 V / 50-60 Hz |

| Installed Power | 1,5 kW |

| Compressed air | 0,7 MPa |

| Air consumption | 20 m3/h |

| Net weight | 320 kg |

| Gross weight | 580 kg |

| Packing – 2 wood boxes (L x W x H) | 1250 x 950 x 1730 mm; 3700 x 480 x 950 mm |