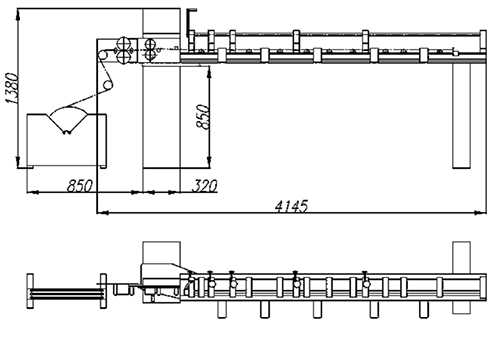

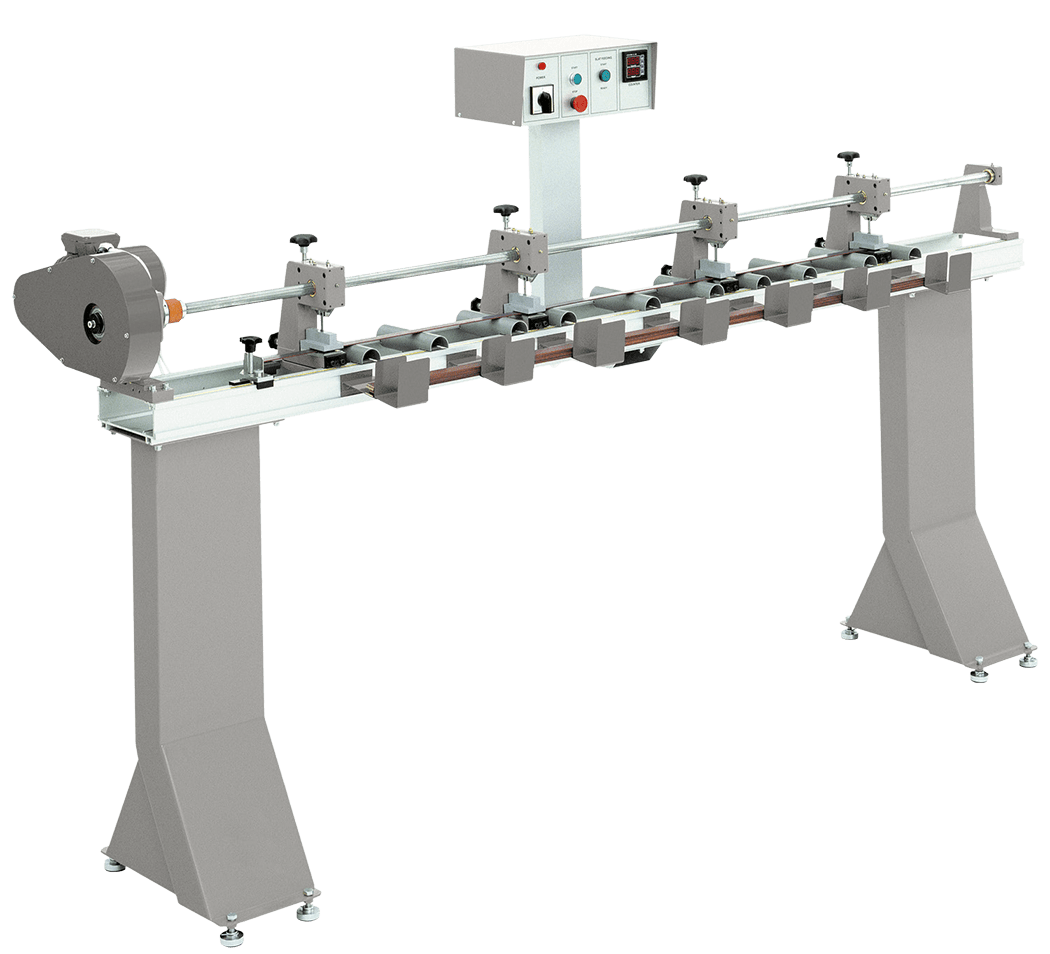

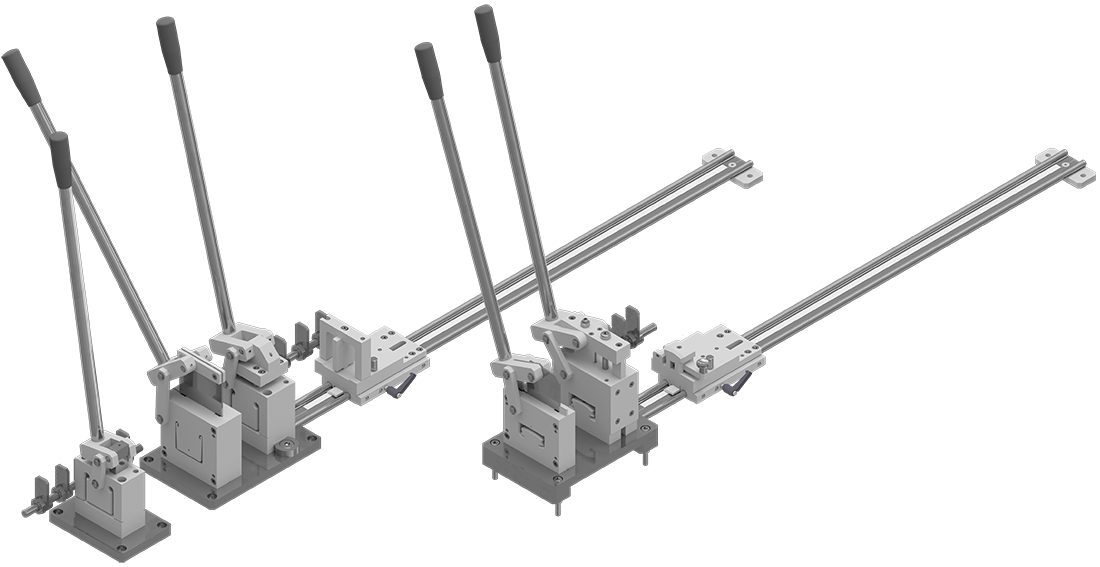

M600

Machine description

M600 manual slat forming, punching and cutting machine. Modular construction allows to upgrade this machine to fully automatic if needed.

Machine features

- Forming, cutting and hole punching in aluminium slats

- Precise setting of slats length and punching stations

- Standard slat width range: 16, 25, 35 i 50 mm

- Quick and easy change between aluminium slats widths without using additional tools

| Slat width | 16, 25, 35, 50 mm |

|---|---|

| Min. length of cut slats | 240 mm |

| Qty of punching stations | 4 |

| Qty of cut off stations | 1 |

| Min. distance from slat edge to first hole | 70 mm |

| Net weight | 140 kg |

| Packing – wood crate (L x W x H) | 3900 x 500 x 730 mm |

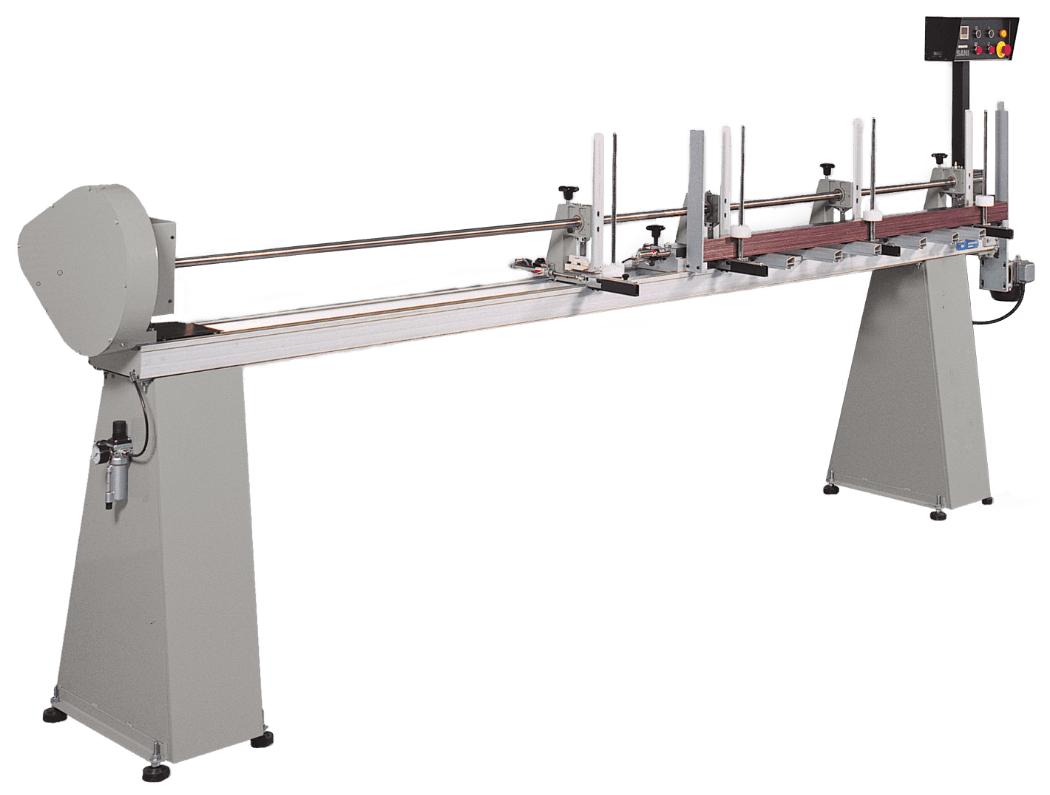

M420

Machine description

M420 is fully automatic slat cutting and punching machine.

Machine features

- Cutting and punching in one cycle

- Precise setting of slat length and punching stations

- Variable speed: 0 – 100 %

- Standard slat width range : 16, 25, 35, 50 mm, on client’s wish

- Quick and easy change between aluminium slats widths without using additional tools

- Automatic qty of slats and hole division calculation

- Possibility to install threading section

- Easy to operate and maintain

Additional equipment

- Side guide hole equipment

- Barcode reader

- Spare parts kit

- Service agreement

| Slats width (on client’s order) | 16, 25, 35, 50 mm |

|---|---|

| Slat length | 210 mm – 3000 mm |

| Qty of punching stations | 4 |

| Qty of cutting stations | 1 |

| Min. distance from slat edge to first hole | 70 mm |

| Max. slat feeding speed | 3 m/sec. |

| Power supply | 230V / 50-60 Hz |

| Installed power | 1,4 kW |

| Net weight | 230 kg |

| Gross weight | 480 kg |

| Packing – wood crate (L x W x H) | 4320 x 700 x 1650 mm |

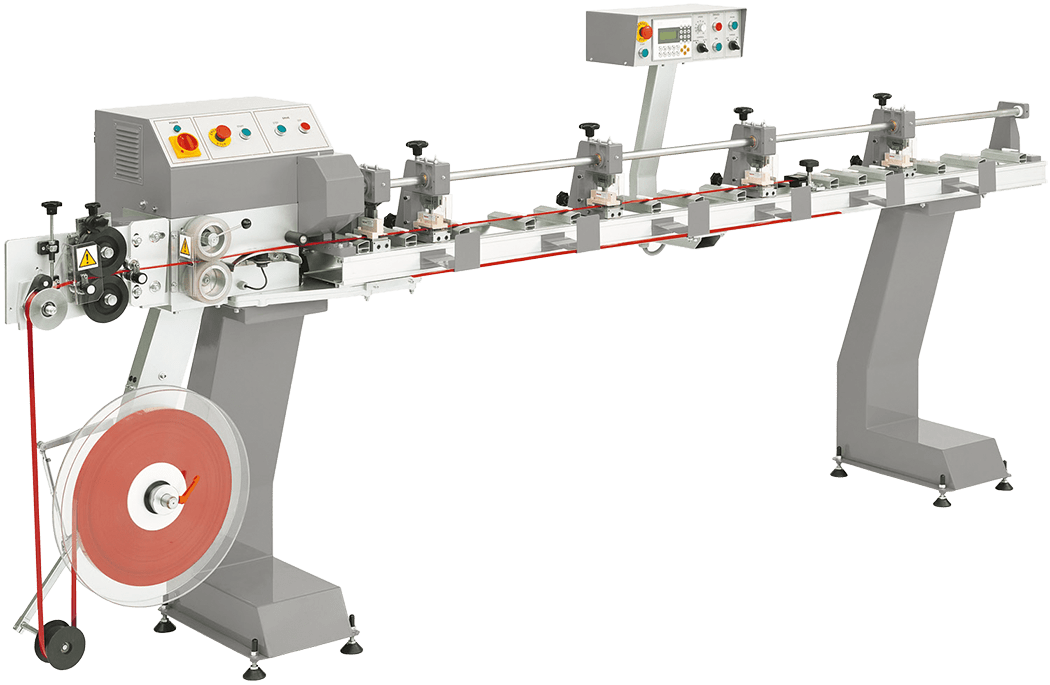

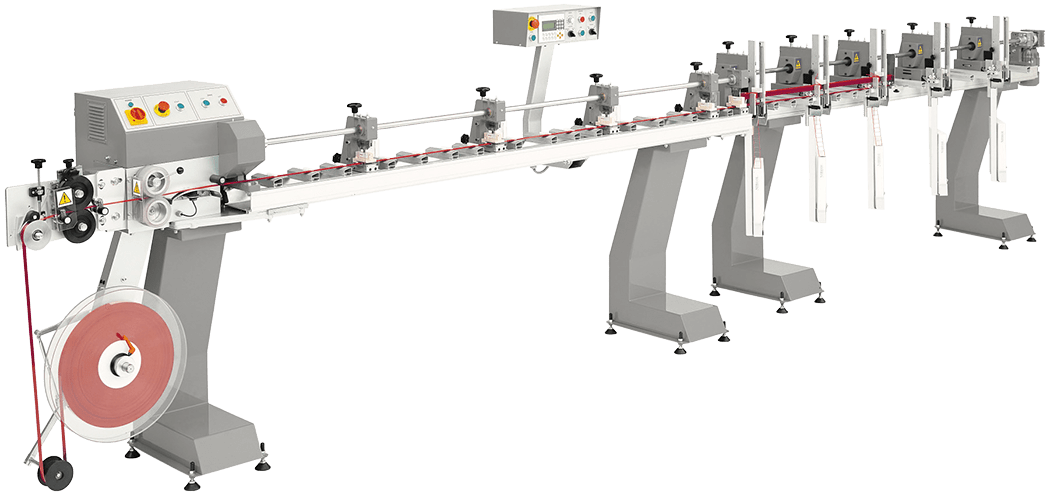

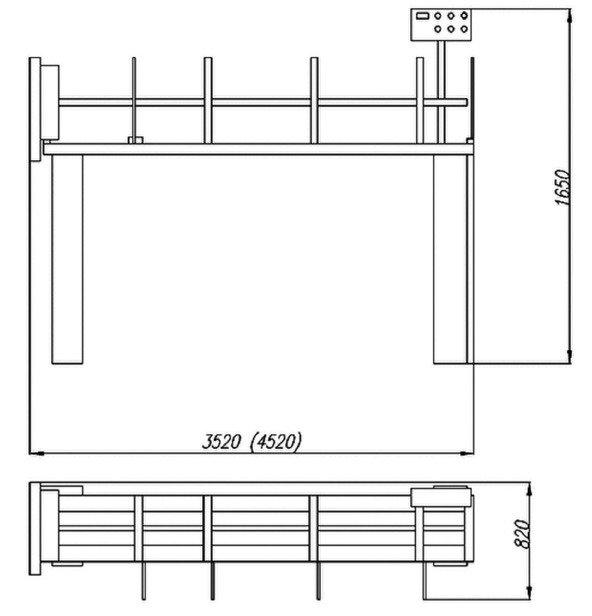

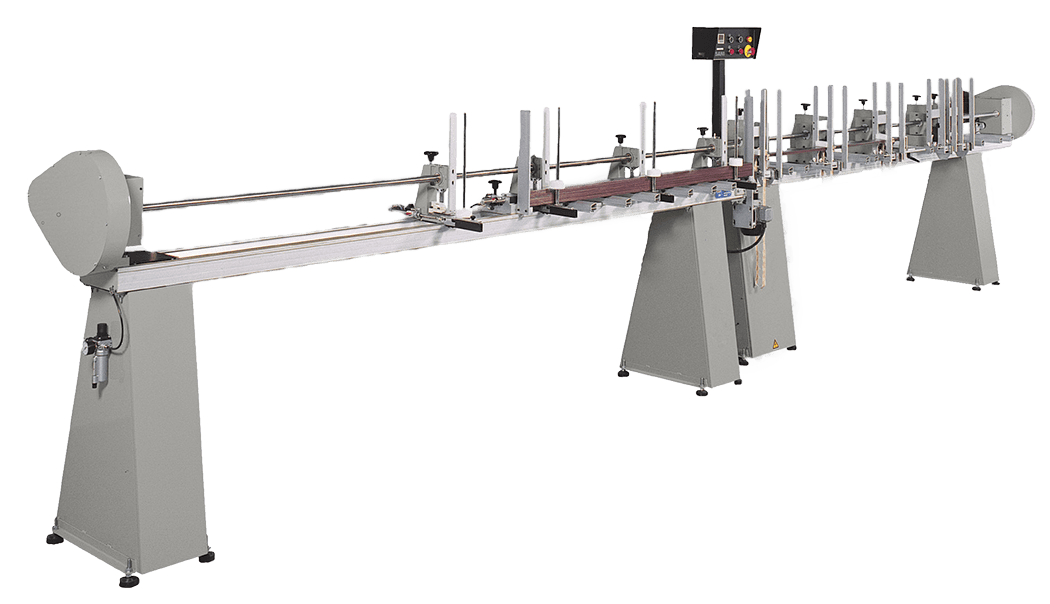

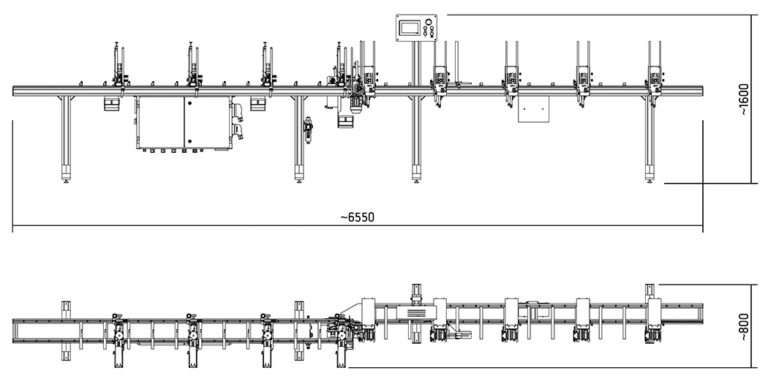

M420T

Machine description

M420T is fully automatic slats cutting, punching and threading machine.

Machine features

- Cutting, punching and threading in one cycle

- Precise setting of slat length and punching stations

- Single or double stacking magazines

- Mechanically disengageable punching dies

- Variable speed: 0 – 100 %

- Standard slat width 16, 25, 35, 50 mm

- Quick and easy change between aluminium slats widths without using additional tools

- Automatic qty of slats and hole division calculation

- Easy to operate and maintain

Additional equipment

- Side guide hole equipment

- Multi blind cutting station (200 MC – compressed air required (0.6 MPa))

- Barcode leader

- Spare parts kit

- Magazines for woven laddertapes

- Short blinds kit (200 SB – compressed air required (0.6 MPa))

- Service agreement

| Cutting length | 290 mm - 3000 mm (longer optional) |

|---|---|

| Qty of punching stations | 4 |

| Qty of cut off stations | 1 |

| Qty of threading stations | 5 – 8 |

| Min. distance from slat edge to first hole | 75 mm |

| Max. slat feeding speed | 3 m/sec. |

| Power supply | 230V / 50-60 Hz |

| Installed Power | 1,9 kW |

| Net weight | 360 kg |

| Gross weight | 720kg |

| Packing – wood crate (L x W x H) | 4700 x 1120 x 1650 mm |

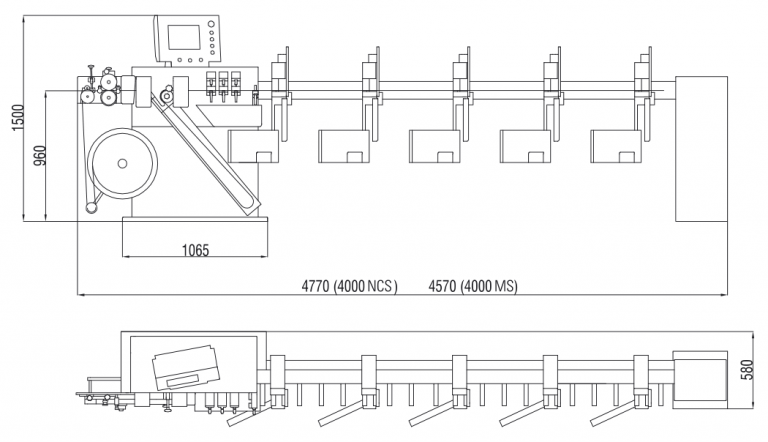

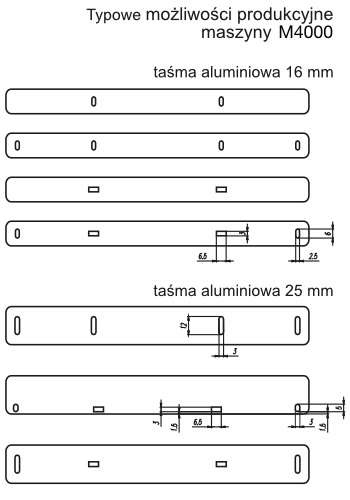

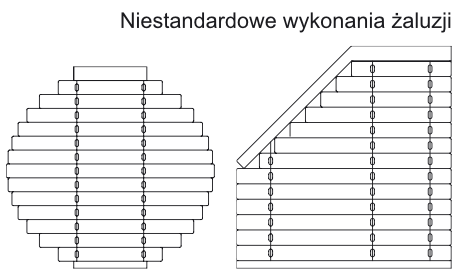

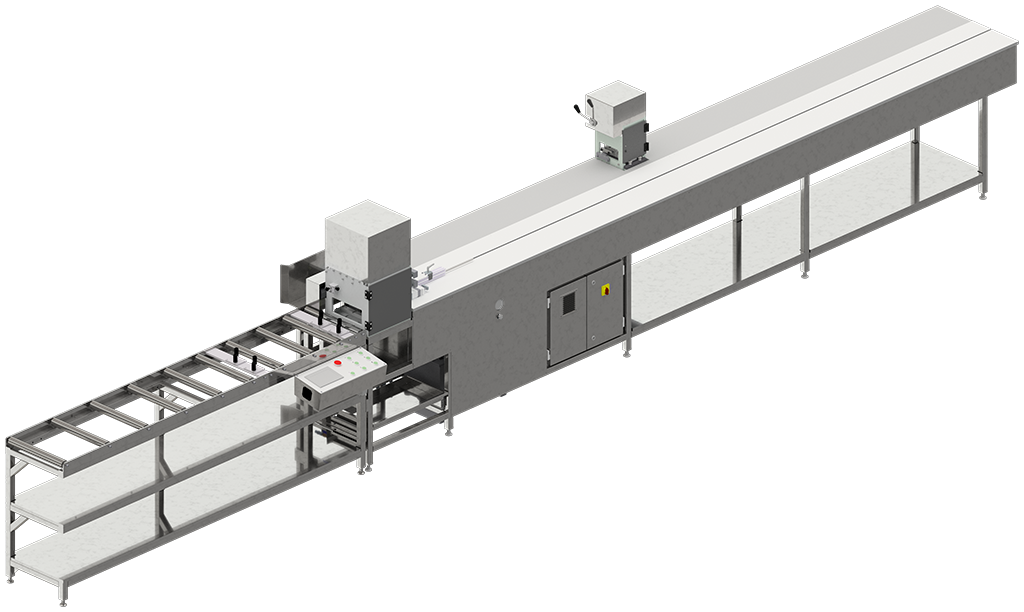

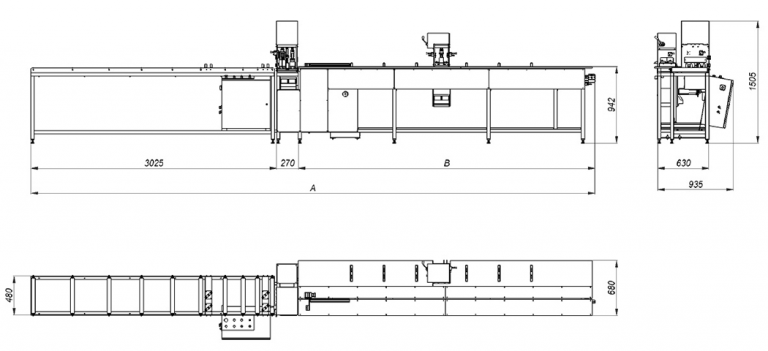

M4000

Machine description

M4000 is fully automatic slats cutting, punching and threading compact machine of 3rd generation.

Machine features

- Forming, punching, cutting and threading

- Production with high accuracy

- Compact machine – less space required

- All systems of venetian blinds production

- Numerically controlled length of slats

- Quick and easy change between aluminium slats widths without using additional tools

- Quick setup of blinds dimensions

- Slat coil holder with a constant slat tension

- Automatic slats number calculation

- Possibility to set another blind during machine work

- Diagnostic through service window or Internet modem

- Continuous readout:

- Productivity

- Qty of produced blinds

- Number of cycles per each die

| Machine type | M4000 NCS | M4000 MS |

|---|---|---|

| Number of punching stations | 3 | 3 |

| Number of cutting stations | 1 | 1 |

| Number of threading stations | 5-7 | 5-7 |

| Slat width range | 16, 25, 35, 50 mm | 16, 25, 35, 50 mm |

| Min. slat length | 300 mm – less without threading | 300 mm – less without threading |

| Max. slat length | 3000 mm, 3500 mm, 4000 mm | 3000 mm, 3500 mm, 4000 mm |

| Min. distance from slat edge | 80 mm – less without threading | 80 mm – less without threading |

| Production speedy (slat package 1 m x 1 m) | 31 sec. | 34 sec. |

| Control panel | 10,4inch colour touch screen | 10,4inch colour touch screen |

| Punching dies setup | automatic | automatic |

| Threading stations setup | automatic | manual |

| Package lifting to higher level | standard | standard |

| Short blinds kit | optional | optional |

| Barcode reader | optional | optional |

| Power supply | 3x400V / 50-60 Hz | 3x400V / 50-60 Hz |

| Installed power | 2,8 kW | 2,2 kW |

| Compressed air | 0,7 MPa | 0,7 MPa |

| Air consumption | 150 L/min. | 150 L/min. |

| Net weight | 440 kg | 395 kg |

| Gross weight | 655 kg | 610 kg |

| Packing – 2 wood boxes (L x W x H) | 1600 mm x 750 mm x 1800 mm | 3650 mm x 800 mm x 1645 mm |

PR-5

Machine description

PR-5 hydraulically powered rail-cutting and punching machinery computerized with manual feeding with interchangeable dies.

Machine features

- Computerized automatic rail cutting and punching machine

- Interchangeable dies make it compatible with most rail systems

- Automatic calculation, only rail width must be entered

- Head and bottom rails punched at the same time

- Equipped with to tools for punching cord lock and tilter holes

- Easy to operate and maintain

- Service and after sale support

Additional equipment

- Software for barcode reader

- Side guide hole dies with on/off function

- Slopped blinds application

- Label printer connection

| Cut length | 3000, 4000, 5000 mm |

|---|---|

| Power supply | 3 x 380/415V 50/60 Hz |

| Weight | 780 kg |

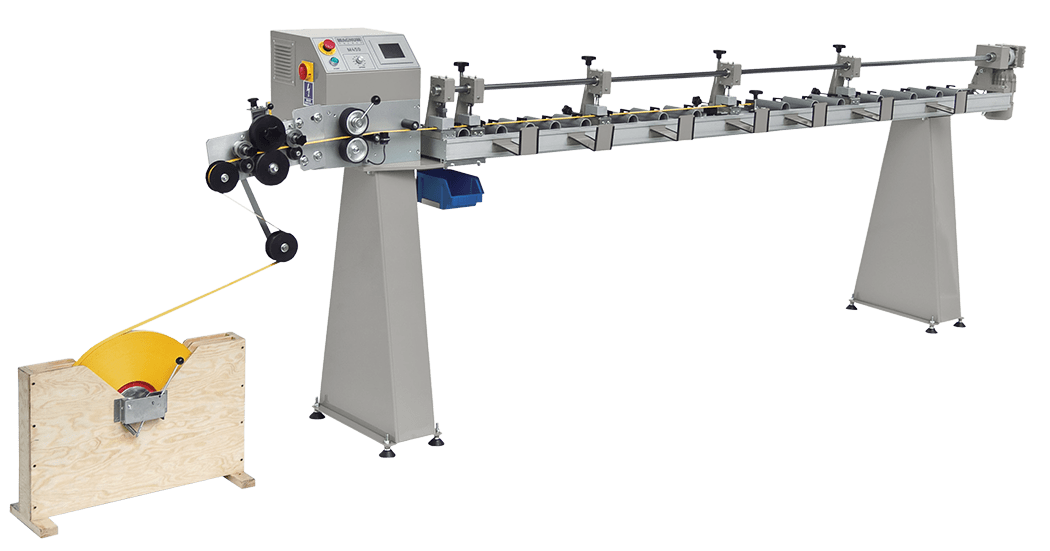

M450

Machine description

M450 is an automatic slat cutting and punching machine designed especially for small and medium blinds manufacturers.

Machine features

- Forming, cutting and hole punching in aluminium slat

- Precise setting of slat length and punching station positions

- Variable speed 0-100%

- Standard slat widths 16, 25 mm

- Quick and easy change between slats widths without using additional tools

- Automatic slat counting during production process

- Modern „touch screen” control panel

Additional equipment

- Side guide cut off die

- 25 mm or 16 mmm slat width equipment

- Warranty and non-warranty service

| Slats width | 16 mm or 25 mm |

|---|---|

| Slat length | 210 mm – 3000 mm |

| Number of punching stations | 4 |

| Number of cutting stations | 1 |

| Min. Distance from slat edge to first hole | 70 mm |

| Max. slat feeding speed | 1,7 m/sec. |

| Power Supply | 230 V / 50-60 Hz |

| Installed Power | 0,95 kW |

| Net weight | 190 kg |

| Gross weight | 490 kg |

| Packing – wood crate (L x W x H) | 4140 x 730 x 1630 mm |

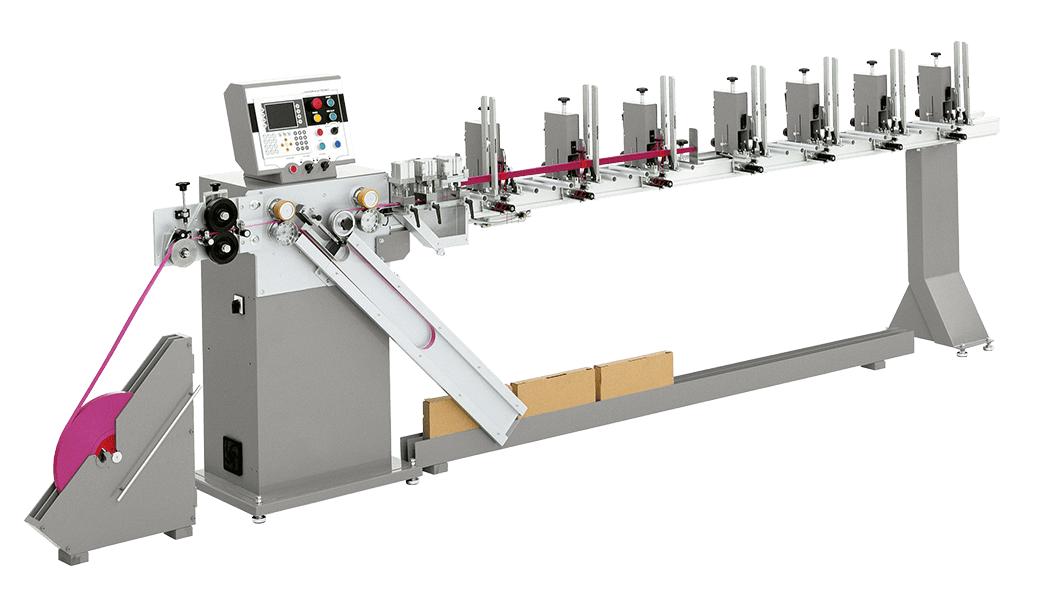

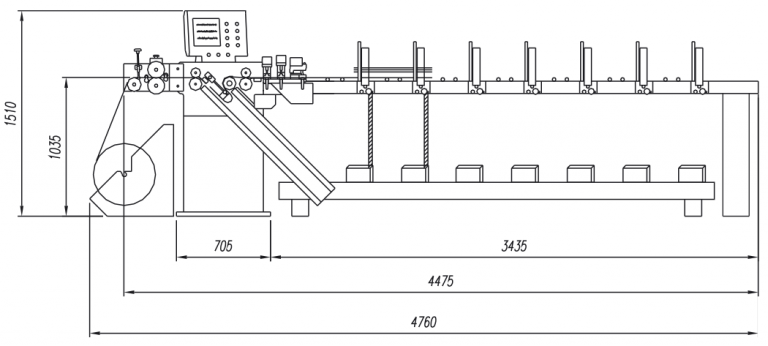

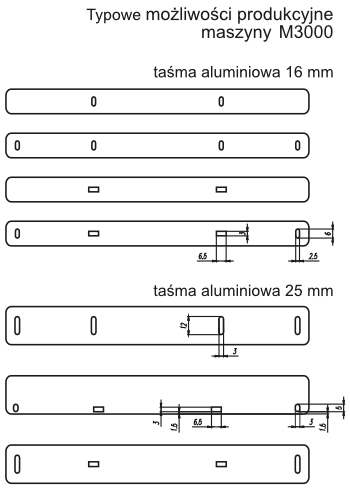

M3000

Machine description

M3000 is a fully automatic slat cutting, punching and threading machine.

Machine features

- Forming, cutting and punching holes in aluminium slats 15, 16 or 25 mm wide and threading of venetian

blinds - All systems of venetian blinds production

- 2 punching stations allowing simultaneous punching of 2 holes

- Possibility of changing distance for side guiding holes

- Threading stations – manual setup

- High precision of blind length and setting of hole distance

- Automatic lift of produced blinds to a higher level – option

- Control panel – functions:

- Quick setup of blinds dimensions, automatic slat number calculation

- Possibility to set 6 types of blinds, also during machine work

- Possibility to choose qty and arrangement of holes and ladderstrings

- Readout of machine performance in m2/h, alu slats usage, qty of produced blinds and qty of cycles per each die

- Diagnostic through service window or Internet modem

| Number of punching stations | 2 |

|---|---|

| Number of cutting stations | 1 |

| Number of threading stations | 4-7 |

| Slat width | 15 mm, 16 mm, 25 mm |

| Min. slat length | 300 mm less without threading |

| Max. slat length | 3000 mm |

| Min. distance from the slat edge to the first hole | 90 mm |

| Machine productivity | 65 m2/h |

| Control panel | 5,7inch Monochromatic |

| Punching stations setup | automatic |

| Threading stations setup | manual |

| Package lifting | option |

| Barcode reader | option |

| Power supply | 3x400 V / 50-60 Hz |

| Installed Power | 1,5 kW |

| Compressed air | 0,7 MPa |

| Air consumption | 20 m3/h |

| Net weight | 320 kg |

| Gross weight | 580 kg |

| Packing – 2 wood boxes (L x W x H) | 1250 x 950 x 1730 mm; 3700 x 480 x 950 mm |

M400RD

Machine description

M400RD is a semi-automatic machine for wooden blinds production.

Machine features

- All holes punched simultaneously

- Slat width range 24-52 mm

- Manual feeding and removing of slats

Additional equipment

- Punching stations for side guiding holes

| Wood slats width | 25 mm, 35 mm, 50 mm |

|---|---|

| Max. length of wood slat | 2500 mm |

| Number of punching stations | 4 |

| Min. distance from slat edge to first hole | 70 mm |

| Power supply | 3x400V / 50-60 Hz |

| Installed power | 0,75 kW |

| Net weight | 160 kg |

| Gross weight | 310 kg |

| Packing – 1 wood box (H x L x W) | 2750mm x 670mm x 1670mm |

216WAF

Machine description

216WAF is a fully automatic machine for production of wooden blinds.

Machine features

- All holes punched simultaneously

- Adaptable for most wooden or composite slats 24-52 mm wide

- Precise setting of slat length and punching stations position

- Easy to operate and maintain

- Spare punches available

- 216WAF can be upgraded to 216W-219W at later occasion

Additional equipment

- Speed control

- Spare parts kit

- Service agreement

| Power supply | 3 x 220/240V (50/60 Hz)nlub 3 x 380/415V (50/60 Hz) |

|---|---|

| Pneumatic equipment requirements | approx. 6 bar at 30 L/min. |

216W-219W

Machine description

216W-219W is a fully automatic machine for wooden blinds production.

Machine features

- All holes punched simultaneously

- Adaptable for most wooden or composite slats 24-52 mm wide

- Adaptable for various slat widths and ladder types

- Precise setting of slat length and punching station positions

- Easy to operate and maintain

- Spare punches available

Additional equipment

- Magazines for woven laddertapes

- Speed control

- Spare parts kit

- Service agreement

| Power supply | 3 x 220/240V (50/60 Hz)nlub 3 x 380/415V (50/60 Hz) |

|---|---|

| Pneumatic equipment requirements | approx. 6 bar at 30 L/min. |

MPW-100

Machine description

MPW-100 is a fully automatic machine for the production of wooden and bamboo venetian blinds, which significantly optimizes the production and improves the comfort of work. The application of unique and thoughtful solutions ensures trouble-free operation of the machine.

Machine features

- Compact pneumatic drive for punching units

- Thanks to the use of a servo drive, making FIX holes does not require additional financial expenses – FIX and system holes are punched with the same tool in one cycle

- Application: wooden, bamboo or wood-like slats, the width range of 24-63.5 mm

- Length range: 370 ÷ 4000 mm

- Possibility to use ladderstring or woven tape

- Precise positioning of punching and folding stations

- Ease of operation and maintenance

- Quick setting of blind dimensions

- Intuitive 7 “touch control panel

Additional equipment

- Speed control

- Set of spare parts

- Service agreement

- Spare punches, ladder magazines available

| Dimensions of punched holes (depending on the option ordered) | other options on request |

|---|---|

| slats 25mm | 3x12 |

| slats 35mm | 4x15 |

| slats o 50mm | 4x20 |

| slats 62,5mm | 4x20 |

| Power supply | 3 x 220/240VAC |

| Pneumatic equipment requirements | approx. 6 bar at 220 L / min. |

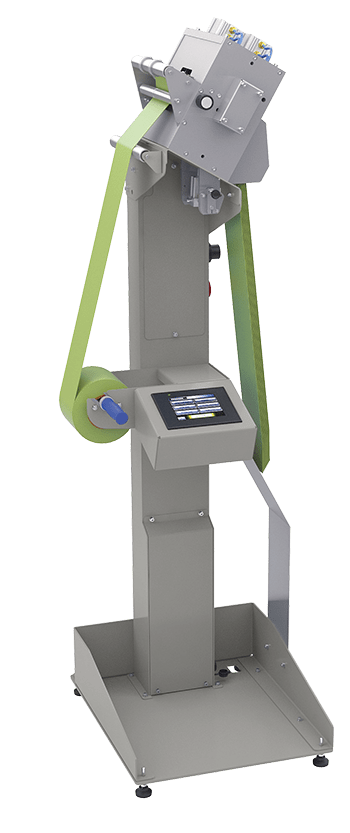

AVC-3

Machine description

AVC-3 is an automatic machine for cost e ective production of vertical fabric vanes. Cutting, punching and creasing is done in one cycle.

The machine can be set up for 89 and 127 mm fabric.

Machine features

- Compact machine – requires minimum of space

- Cutting, punching and creasing in one cycle

- Bottom and top pocket width electronically adjustable

- Easy to change setup between sizes without using additional tools

- Programmable for window fit and vane size

- Vanes collected on a hanger peg

- Warranty and non-warranty service

- Excellent cost performance ratio

| Max. vane length | 10 m |

|---|---|

| Top pocket range | 5-100 mm |

| Bottom pocket range | 16-100 mm |

| Offset adjustment | 0-100 mm |

| Fabric feeding speed | 0,6 m/s |

| Power supply | 230 V (50/60 Hz) |

| Pneumatic equipment requirements | approx. 6 bar at 150 L / min |

| Overall size | Height = 1840 mm Width = 610 mm Depth = 500 mm |

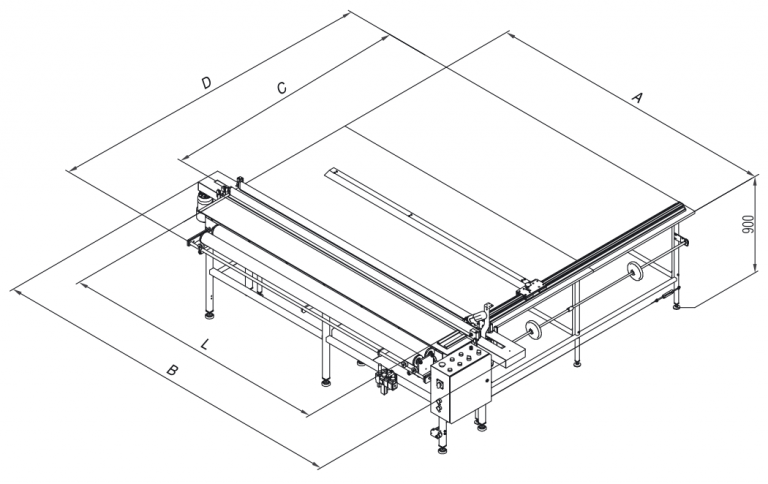

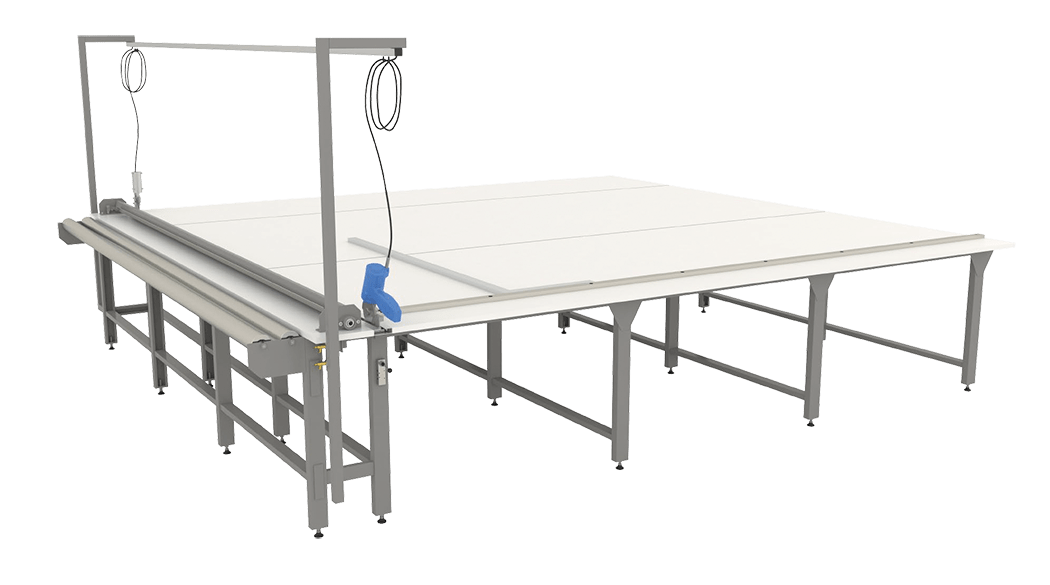

SV-P1

Machine description

Table for cutting roller blinds with an electronic rotating knife.

Machine features

- Back lighted area enables easy fabric defects detection

- The fabric is cut by electric rotating knife

- Steel line controls the pneumatic pressure

- Movable carriage to correct fabric alignment

- Automatic knife feeding

Additional equipment

- Ultrasonic cutting device

| Max. fabric roll diameter | 170 mm |

|---|---|

| Max. fabric roll weight | 40 kg |

| Power supply | 230 V / 50-60 Hz |

| Min. air pressure | 0,4 MPa |

| Air consumption | 8 L / min. |

RBH-02 / EP

Machine description

Manual roller blinds cutting table with electric rotating knife.

Machine features

- Very stable framework securing proper geometry and stability

- Pneumatic fabric clamp system

- Top class rotating knife SUPRENA

- Ultrasonic cutting device as an option

MK-003HR-25 / MK-003BR-25

Tool description

Punching distance and length scale 1,2 mtr can be used for for cutting H / B rails and for setting distance of punched holes. It works with punching tools for V13 systems. Cutting tolerance +/-0,5mm. Frame made of aluminium. Required joint assembly on the table.

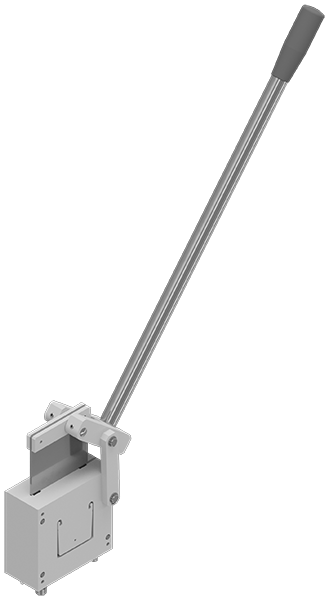

MK-032

Tool description

Punching tool for punching all system holes (tilter, cordlock) in head rails. The distance of the holes is set by the stopper which defines the right valance position allowing punching holes in the preferable distance. Manually operated with a lever. Designed for V13 systems.

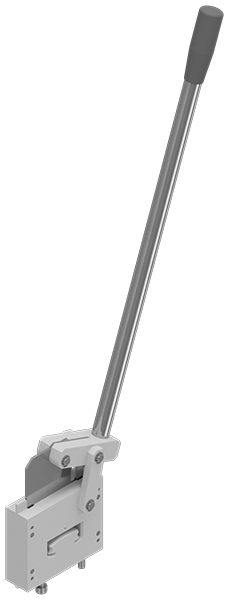

MK-007

Tool description

Cutting tool MK-007 is used for cutting head rails to desired lengths. Manually operated with a lever.

Can be used for V17 systems.

MK-008

Tool description

Cutting tool MK-008 is used for cutting bottom rails to desired lengths. Manually operated with a lever.

Can be used for V17 systems.

MK-009-C / MK-009-R / MK-013

Tool description

Punching tool is used for punching all system holes in head rails (cordlocks, titlers, bearing brackets). The distance of the holes from the edge of the bottom rail is fixed via bumper. Manually operated with a lever.

Can be used for V17 systems. Hole measurements are shown in standards for the given system.

MK-010

Tool description

Punching tool MK-010 is used for cutting holes in bottom rails (tape lock button). The distance of the holes is set by the stopper which defines the right valance position allowing punching holes in the preferable distance. Manually operated with a lever.

Can be used for V17 systems. Hole measurements are shown in standards for the given system.

Dies for cutting and punching holes in decorative steel slate

Tool description

Dies for cutting and punching holes in a decorative steel slate. The number of holes is determined by the bumper, which is responsible for the correct position of the decorative steel slate, allowing holes to be punched at an appropriate distance.

Tools are manually operated dies that are suitable for V13 systems. The dimensions of the holes are included in the production standards for each system.

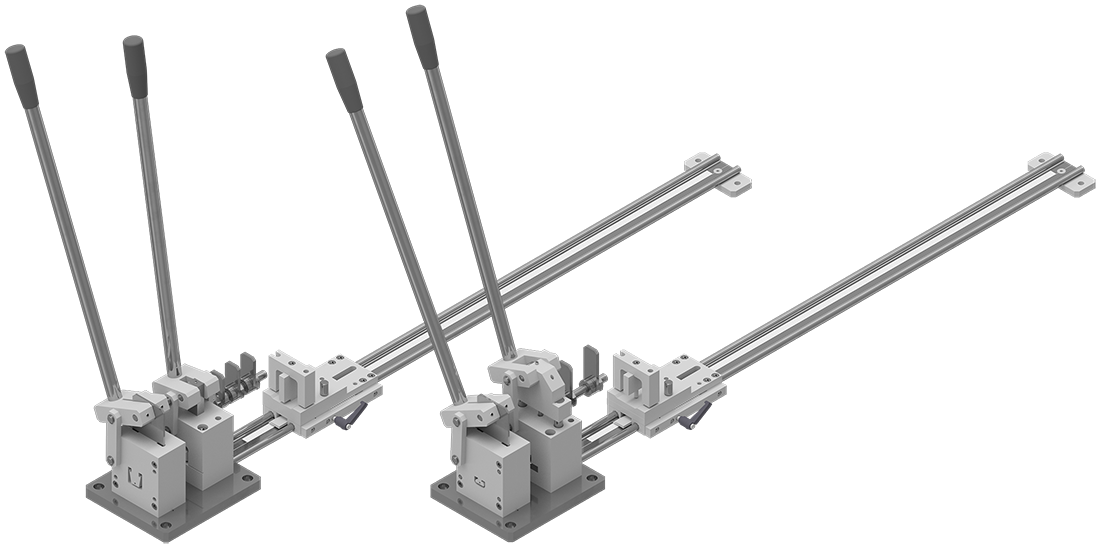

MK-3033003HR-25 / MK-3134003BR-25

Tool description

Compound tool for cutting head / bottom rails, punching holes for bearing brackets in head rails and holes for tape lock buttons in bottom rails. Manually operated with a lever. Can be used for V13 systems.

Hole measurements are shown in standards for the given system.

MK-030 / MK-031

Machine description

Cutting die is used for cutting head rail/bottom rail to required lengths. Tool is manually operated with leverage dies. Designed for V13 systems.

MK-033

Machine description

Punching die of bearing bracket for head rail. The distance of the holes from the edge of the head rail is fixed via bumper. Tool is manually operated with leverage dies. Designed for V13 systems.

MK-034

Machine description

Punching die of tape lock button for bottom rail. The distance of the holes from the edge of the bottom rail is fixed via bumper. Tool is manually operated with leverage dies. Designed for V13 systems.

MK-003HR-50 / MK-003BR-50

Machine description

Punching distance and length scale 1,2 mtr can be used for for cutting H / B rails and for setting distance of punched holes. It works with punching tools for V17 systems. Cutting tolerance +/-0,5mm. Frame made of aluminium. Required joint assembly on the table.

MK-0709RC003HR-50 / MK-0810003BR-50

Machine description

Compound tool for cutting head / bottom rails, punching system holes in head rails and holes for tape lock buttons in bottom rails. Manually operated with a lever. Can be used for V17 systems.